The Irish chemist Peter Woulfe may have been one of the last practicing alchemists. In his later years, he was known as an eccentric, perhaps deranged, person, who attached prayers to his chemical apparatus, and attributed his failures at transmuting base metals to gold and finding the elixir of life to not having performed enough pious and charitable acts. In his more lucid days, however, he was a Fellow of the Royal Society of London, and made several important contributions to the study of chemistry. He was a recipient of the prestigious Copley Medal "For his Experiments on the Distillation of Acids, Volatile Alkalies, and other substances".

In 1771, he reports in the Philosophical Transactions of the Royal Society, his experiments with nitric acid on the blue dye indigo (the same dye used for coloring blue jeans):

A Method of dying Wool and Silk of a yellow colour, with Indigo; and also with several other blue and red colouring Substances.

The Saxon blues have been known for some time; and are made by dissolving indigo in oil of vitriol [sulfuric acid], by which means the indigo becomes of a much more lively colour, and is extended to such a degree, that it will go very far in dying.

A receipt for making the best Saxon blue will, I dare say, be agreeable to many; I will, therefore, give the following, which produces a very fine colour, and never fails in success.

Mix 31 of the best powdered indigo, with 34 of oil of vitriol in a glass body or matrass: and digest it for one hour with the heat of boiling water, shaking the mixture at different times; then add 312 of water to it, and stir the whole well, and when grown cold filter it. This produces a very rich deep colour; if a paler blue be required, it may be obtained by the addition of more water. The heat of boiling is sufficient for this operation, and can never spoil the colour; whereas a sand heat, which is commonly used for this purpose, is often found to damage the colour, from its uncertain heat.

Indigo, which has been digested with a large quantity of spirit of wine [ethanol], and then dried, will produce a finer colour than the former, if treated in the same manner, with oil of vitriol.

No one, that I know of, has heretofore made use of the acid of nitre [nitric acid], instead of the acid of vitriol; and it is by means of the former that the yellow colour is obtained: it is nevertheless natural to use it, on account of its known property of making yellow spots, when dropped on any colored cloth.

The acid of salt [hydrochloric acid] does not dissolve indigo, and therefore is of no use in dying.

Receipt for making the yellow dye.

Take 31/2 of powdered indigo, and mix it in a high glass vessel, with 32 of strong spirit of nitre, previously diluted with 38 of water; let the mixture stand for a week, then digest it in a sand heat for an hour or more, and add 34 more of water to it; filter the solution, which will be a fine yellow colour.

Strong spirit of nitre is liable to set fire to indigo; and it is on that account that it was diluted with water, as well as to hinder its frothing up. 321/2 of strong spirit of nitre will set fire to 31/2 of indigo; but, if it be highly concentrated, a less quantity will suffice.

If the indigo be digested for twenty four hours after the spirit of nitre is poured on it, it will froth and boil over; but, after standing a week or less, it has not that property.

One part of solution of indigo in the acid of nitre, mixed with four or five parts of water, will dye silk or cloth of the palest yellow colour, of any shade to the deepest, and that by letting them boil more or less in the colour. The addition of alum is useful, as it makes the colour more lasting; according as the solution boils away, more water must be added.

None of the colour in the operation separates from the water, but what adheres to the silk or cloth; a consequence this colour goes far in dying.

Cochineal, Dutch litmus, orchel, cudbear, and many other colouring substances treated in this manner, will all dye silk and wool a yellow colour.

The indigo which remains undissolved in making Saxon blue, and collected by filtration, if digested with spirit of nitre, dyes silk and wool of all shades of brown inclined to yellow.

Cloth and silk may be dyed green with indigo; but they must first be boiled in the yellow dye, and then in the blue.

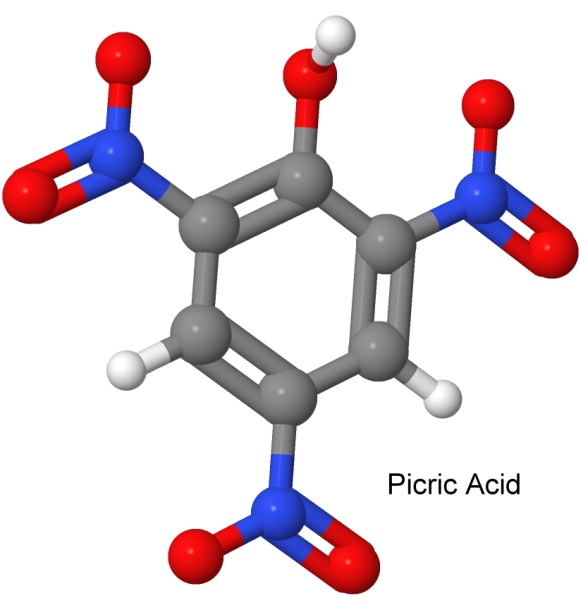

The yellow dye Woulfe created is today known as Picric Acid, or more formally, 2,4,6-trinitrophenol.

Picric acid is a yellow crystalline solid. It dissolves in water forming a highly acidic solution. It was used as an antiseptic for bandages and as a burn treatment, but its toxicity and tendency to form sensitive explosive salts on contact with metals such as copper, iron, lead, or the calcium in concrete caused problems, and these uses were discontinued.

Picric acid by itself is not a sensitive explosive. However, because it is a strong acid, it easily forms salts with metals, and these salts are often quite sensitive to heat, friction, or percussion. As we have seen, primary explosives (those that are easily set off) are easily recognized, as during normal handling in the laboratory they make their nature quite clear, often with injuries. Secondary explosives, those that are insensitive to shock and heat, are often not recognized as explosives for some time. Picric acid is one such example.

The French chemist Jean-Joseph Welter found the same molecule when he nitrated silk in 1799. He experimented with its explosive properties that year. In 1809, the French chemist Michel Eugène Chevreul demonstrated it was an acid, and contained nitrogen. The French chemist Jean-Baptiste-Andrè Dumas named it picric acid, from the Greek word for bitter. It was not known that Welter's Bitter, as it was called, was the same as Woulfe's yellow dye until the German chemist Justus Freiherr von Liebig experimented with both, and pronounced them the same substance. Liebig named it carbazotique acid in 1828. Both names were in use for some time.

In 1842, the French chemist Auguste Laurent made it from phenol (known then as carbolic acid), and showed that three of the hydrogen atoms in phenol had been replaced by NO2 groups, and named it tri-nitro-phenic acid. In 1869, he found an easier method of preparing it using phenol sulphonic acid as the base. That compound is made by dissolving phenol in concentrated sulfuric acid.

By 1867, industrial processes were in place for making picric acid, ammonium picrate, and potassium picrate. In that year the Italian chemist Luigi Borlinetto made a mixture of potassium chlorate and picric acid to use as an explosive, but it was too sensitive. It did find use as a flash powder for photography. He went on to try a mix of picric acid with potassium dichromate, which was more powerful than black powder as an explosive, but apparently not accepted as a replacement.

In 1873, the German chemist Hermann Sprengel showed (again) that picric acid could be detonated. By 1886, the French had created a bursting charge for artillery shells made of picric acid and nitrocellulose, which they called Melinite. The advantage of picric acid for this use was that it was not so sensitive that the shells would explode inside the cannon from the sudden acceleration of the modern propellants.

The British made an explosive using the same ingredients they called Lyddite, after the town of Lydd, where it was manufactured, and in 1894, the Russian military was also filling shells with picric acid. A related explosive, ammonium picrate, was called Dunnite (or explosive D) by the U.S., in 1906.

Picric acid was used by British forces retaking the Sudan in 1898, and again in the Second Boer War (1899 to 1902), by both sides in the Russo-Japanese War (1904-1905), and by all sides (particularly the French) in World War I (1914 to 1918), although by 1902 Germany had begun to use TNT.

Picric acid caused problems when it reacted with the metal casing of shells, forming metal picrates that are much more sensitive to percussion, friction, and heat. The metal was often protected by tin plating (tin does not react with picric acid) or asphaltum, which helped, but could be scratched off in handling. Nothing could be done about the sensitivity of metal picrates to heat, however. On May 1, 1916, a French ammunition factory caught fire, and melted picric acid poured onto the concrete floor, where it reacted with the calcium in the concrete. The heat of the fire detonated the calcium picrate, which then detonated the picric acid. The blast destroyed the factory, and killed 170 people.

On December 6, 1917, the French cargo ship SS Mont-Blanc left Halifax Harbor in Nova Scotia, fully loaded with explosives for use in the war, mostly picric acid, but also TNT, guncotton, and high-octane fuel. In a narrow strait in the harbor, it collided at low speed (about one mile per hour) with an unloaded Norwegian vessel, leaving for New York to collect relief materials for Belgium. The collision resulted in a fire aboard the SS Mont-Blanc. Twenty minutes later, the Mont-Blanc exploded, in the largest chemical explosion ever seen, releasing the equivalent of 2.9 kilotons of TNT. Structures within a half mile were obliterated, including the entire town of Richmond, killing 2,000 people and injuring 9,000. The explosion caused a tsunami that wiped out a community of indigenous people of the Mi'kmaq tribe.