As the quality of the black powder improved (largely through the use of more potassium nitrate with higher purity), the fire lance improved along with it. The new powder shot the flames out with more force. Bits of metal and broken pottery could be added, and this shrapnel would shoot out towards the enemy with enough velocity to cause injury.

With the advent of metal tubes instead of bamboo, stronger powder, and projectiles, the fire lances became too heavy to hold by hand, and they added wheeled carts to move them around more easily. These "erupters" as they were called, defended fortifications. Some shot multiple arrows from the tubes, and some shot metal balls. As the projectiles grew to fill the mouth of the tube, the force of ejection increased. When the powder was no longer used for its flame, and instead was used only to propel projectiles, the true gun had arrived.

Handguns made with metal barrels were in use by the late 1200's. One gun, found in 2004, is inscribed with the date 1271, five years before the Mongols overran the Southern Song. It was made of copper, and shaped like an elongated vase, bulbous in the rear where the powder exploded. Weighing a little over three pounds, it was about 13 inches long, and had a one inch bore.

Another gun, excavated at an archaeological dig in Heilongjiang, dates to 1288. Like the earlier weapon, it also has a one inch bore, but the bulbous rear had already become a simple tube. It was made of cast iron, with reinforcing hoops of iron at intervals along the barrel, reminiscent of the nodes of a stalk of bamboo.

By 1276, Kublai Khan and his Mongols, now known as the Yuan dynasty, had conquered the Song dynasty in the south, once again uniting all of China under one rule. The Mongol Empire stretched from China all the way west to Russia and the Middle East. While Mongol cavalry, tactics, and sheer numbers were responsible for the military successes, guns and gunpowder played a role in several important battles. The Song used explosive land mines in 1277 against the Mongol invaders, who nonetheless prevailed, using that technology later. The trigger was a pull of a cord that struck flint against steel to spark the explosion.

While the hand cannons used by Chinese fighting under Mongol rule in Manchuria in 1288 had the hooped cylindrical form described earlier, some larger artillery pieces still used the more bulbous shape as late as 1350. When better metallurgical techniques allowed higher strength materials, the cylindrical form made its way into larger guns.

The Red Turban Rebellion that eventually led to the toppling of the Mongol Yuan Dynasty in the mid 1300's used cannons that fired arrows in battles on land as well as at sea. The Ming Dynasty that followed used cannons in battles in the south in the late 1300's, but it wasn't until later that we see them used in the north, particularly in 1414, when used against the western Mongol Oirats, reportedly killing several hundred. The impressive noise of the cannon is thought to have helped in the victory.

Much later, in 1593 at the siege of Pyongyang, the Ming used cannon effectively against a Japanese army that matched them in size, but lacked the firepower. The Japanese were defeated in a single day, due for the most part to the superior weaponry.

The Mongols had brought guns and gunpowder to the Middle East, and Muslim armies brought them into Spain in the early 1200's. Cannons played a part in the siege of Seville, helping Christian armies to take the city in 1248.

Hand cannons found use as early as 1260 in the battles between the Mongols and the Muslim Mamluks, in Ain Jalut, just north of Jerusalem. The Egyptian Mamluks were using hand cannons to frighten Mongol horses and cause disorder.

In 1274, the sultan Abu Yaqub Yusuf used cannons in the siege of Sijilmasa in Morocco.

Farther north, gunpowder was known in England as early as 1216, when Roger Bacon first wrote about it. In 1248, he published a formula for it, and described its military uses. Cannons were used to fire arrows and small metal balls (grapeshot) in the mid 1300's (during the Hundred Year's War) in England and France. In the later 1300's, wheeled cannon started to appear.

Small cannon and firearms were cast from bronze or iron. The ability to cast larger pieces, however, took much longer to develop. In the meantime, the art of the blacksmith was put to use, and cannon were made from wrought iron. A large wooden pole was used as a core, and bars of red-hot iron were pounded to together to weld them into a single piece around the pole. The next step used technology borrowed from the makers of wine barrels. Hoops of iron were brought to red heat to make them expand. They were then slipped over the wrought iron bars and allowed to cool and shrink around them, reinforcing the bars against the pressure of the exploding powder. It was this technology that gives the name to this part of the gun — the barrel.

The powder was put into a separate chamber (called the powder chamber). Once the powder was poured into this upright chamber, a wooden bung was tamped into place on top, and the whole thing turned horizontally and attached to the end of the barrel. The powder chamber had a smaller bore than the cannon barrel, so the walls could be thicker to withstand the explosion. A red-hot poker was brought to the touchhole to set it off.

The balls for these cannon were made from stone, shaped into rough spheres by stonemasons. One of the big Flemish bombards (built in 1450) weighed 18 tons, and fired stone balls two feet in diameter.

Cannons were used to defend Constantinople in 1396, but later (in 1422) the Ottoman attackers returned with improved large cannon of their own, that could send stone balls weighing hundreds of pounds to distances over a mile. These huge bombards (one was 27 feet long) took hours to reload, and were dragged to battle by teams of 60 oxen and 400 men.

These huge guns were cast from copper, not made of wrought iron. The wrought iron guns could not stand up to the power of the new powders. The casting was done at the site of the siege, as the guns were enormous, (one had a barrel 26 feet long and shot a stone weighing over a thousand pounds). Fifty oxen were needed to move the gun, and the crew that fired it numbered seven hundred men. The first stone shot from the gun went farther than a mile, and buried itself six feet into the ground.

Cast cannons could no longer be breech loaded. The powder chamber was now part of the whole gun, cast in the same pour as the barrel. The guns were now loaded from the muzzle end. The new corned powder made this a much easier task than it would have been with the older finely ground powder.

Cannons changed the way Europeans built fortifications. Old-fashioned castle walls were vulnerable to cannon fire, the flat stone walls taking the impact directly, the stone shattering. Replacing them were star formations, with sloping sides made of earth, sometimes faced with stone or brick( which did not shatter like stone), to deflect the cannonballs before they could get to the actual walls. The star formation allowed defenders to fire on anyone trying to dig under the walls, as there was nowhere to hide.

Field artillery continued to improve by the late 1400's. Cannons on wheels allowed mobile forces more firepower and more options in its deployment. The barrels of the cannons were cast with side projections near the center of mass, called trunnions, so changes in elevation were easier and faster to make. No longer just used for battering at walls, the wheeled artillery was now used against troops, cavalry, and enemy cannon. Cannons became smaller as improved metallurgy and better powder allowed higher velocities. The lighter cannon were easier to move around and took less time to load.

Despite these improvements, field cannon still moved at a walking pace at best, and much of warfare was done with small arms and pikes. Small firearms such as the hand cannon, which were fired by touching a flame or hot coal to the powder in a touch hole, made way for the arquebus, a shoulder-fired long gun that was fired by moving a lever to lower a lit piece of cord (a "match") onto the powder. This allowed the user to keep his eyes on the target, and both hands on the weapon. Such "matchlock" guns had a small cup, called a flash pan, that held the priming powder on the side of the gun, connecting to the touch hole, which was no longer on the top of the barrel. The barrel was flared at the muzzle end to make it easier to muzzle-load the powder and ball. The mechanism was called a "lock" because it resembled the lock on the door of a house. We get the phrase "lock, stock, and barrel" from the three main parts of a gun.

With the arquebus came the invention of volley fire, where once the front rank of guns had fired, a second rank took their place, and then a third, by which time the first rank had been able to reload. With this innovation, the arquebus became the main tool for armies, instead of being merely a support piece. By the late 1400's and early 1500's they were used in large numbers on the battlefield, and Cortes brought some with him to Mexico during his conquest of the Aztecs.

Matchlock weapons had many drawbacks. In wet weather, the match often went out. Carrying a lit match when loading a firearm or handling gunpowder was obviously dangerous. The matches were visible at night, and the odor of the burning match carried far downwind, making surprises less likely. On top of that, the match had to stay lit for long periods, which required a large supply of the saltpeter impregnated cord.

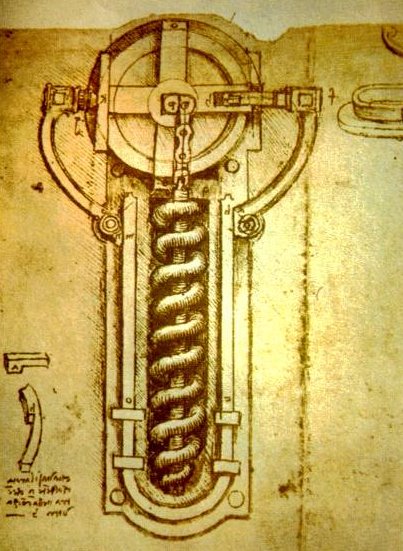

The next improvement was the wheel-lock, which was invented around the year 1500. Some think it was invented by Leonardo Da Vinci, who drew the image below, but there is evidence it was previously invented by an unknown German. A pull of the trigger caused a steel wheel to spin very quickly, rubbing against a piece of iron pyrite to produce a spray of hot sparks. These would hit the primer powder in the flash pan, and fire the weapon. Such self-igniting guns overcame many of the disadvantages of the matchlock. The flash pan now also had a cover, (slid out of place by the trigger mechanism) that kept the powder in place and dry.

Wheel-lock weapons were complex and difficult to manufacture. Later mechanisms such as the snaplock and flintlock used a flint that hit a piece of steel, sending white-hot steel fragments into the flash pan. These were cheap to manufacture, and generally replaced wheel-lock weapons everywhere. The steel part the flint hit (called the frizzen), is an integral part of the flash pan cover. As the sparks are created, the frizzen is kicked out of the way, opening up the flash pan to receive the sparks.

By the mid 1500’s, gunpowder manufacturing had improved considerably. The nitrate percentage was improved to 75%, and the powder was corned. Corning the powder meant forming it into larger pieces (by extruding it through a sieve). This allowed the flame front to quickly move through the open spaces between the grains, causing the entire charge to ignite at once, instead of having to burn through packed powder from one end to the other. Since the powder was still finely ground before corning, the oxidizer and fuel were still in very close contact, and the powder burned very fast.

By the late 1500’s, cast-iron had replaced stone balls as projectiles, and cannon bores were standardized, so that mass produced balls would fit the artillery pieces closely, ensuring a better seal. The improved gunpowder and metallurgy allowed smaller artillery pieces to be very effective, as the speed and range of the projectiles increased.

While the Chinese had been throwing explosive bombs for quite some time, using trebuchets and catapults, cannon that could do this effectively began to appear in Europe in the mid 1300’s. Exploding shells were used in battles in Italy in 1376 and 1421. These shells had fuses that were loaded facing the main powder charge in the cannon, and the timing of the explosion was an issue. If the fuse was too short, the shell would burst in air prematurely, or burst inside the cannon. A fuse that was too long would allow the enemy time to run from the bomb. To ensure that the fuse was always facing the powder charge, a wooden sabot (shoe) was attached to the spherical projectile.

Shells were particularly effective when combined with the mortar, a short cannon used for sending shells upwards over walls, hills, or other fortifications.

For the most part, cannons continued to shoot solid spherical balls well into the 1800’s. Solid shot was easy to manufacture, and had few of the technical problems that exploding shells had.

In 1784, Henry Shrapnel invented a shell that contained a mixture of musket balls and black powder, connected to a time fuse. The shell would explode in mid-air, and release the musket balls, which, because of the initial velocity of the shell, carried deadly force over a wide range onto unarmored infantry.

Rifled cannons began to appear as early as 1840. Rifled small arms were common by then, but the technology to rifle large barrels took longer to develop. Rifling spins the projectile, giving it better accuracy, but it also brings with it other advantages. In order for the rifled barrel to spin the bullet or shell, the projectile must fill the barrel. Muzzle loaded smoothbore cannon fired shot that was smaller than the cannon bore, to make it easier to load. Various schemes to close the gap between the bullet and the bore included expanding copper dishes behind the shell, and lead rings around the rear of the shell that engaged the rifling. These trapped the gas, and allowed as much as twice the amount of gas to actually move the projectile.

Muzzle loaded rifled barrels (whether small arms or cannon) were difficult to load, as the bullet or shell had to be rammed past the rifling. Smooth-bore muskets were the common tool of the military long after the rifle was invented, because it was much faster to load. That began to change in the mid 1800's. In 1823, the Captain John Norton of the British 34th Regiment saw natives in South India using blowguns. He saw how the pith behind the blowgun dart expanded to fill the tube when pushed by the user's breath.

In 1832, Norton invented a cylindrical bullet with a cone at the front, with a hollow base that would expand when the powder exploded. This sealed it against the bore of the gun, so that no gas escaped around the bullet. The result was much faster acceleration, and a higher muzzle velocity. In 1836, a London gunsmith William Greener improved the design by making the bullet oval with a flat base, with a hole drilled into it. A conical plug with a wooden base fit into the hole. When the powder exploded, the cone pushed into the bullet, widening it to form a good seal.

In 1849, two French army captains, Claude-Étienne Miniè and Henri-Gustave Delvigne created a soft-lead bullet with a hollow base, surrounded by several grooves to hold grease. The bullet was cylindrical and longer than a musket ball, but still narrow enough to easily drop down the barrel of a rifle.

The British used this new bullet in the Crimean War to devastating effect against the Russian soldiers, who were equipped with older smoothbore muskets. The longer range and greater accuracy, combined with the deadly effect the new faster bullets had on flesh and bone, made newspaper headlines in the London Times. They called the Miniè equipped rifle "the king of weapons".

The United States had military observers at the Crimean War battles, and the new bullets impressed them as much as they had the Times. The armorer at the U.S. Arsenal at Harper's Ferry, Virginia, John Burton, adapted the new bullet for mass production, getting rid of the drilled hole and conical base with its wooden disk, and replacing those design features with a simple hollow base.

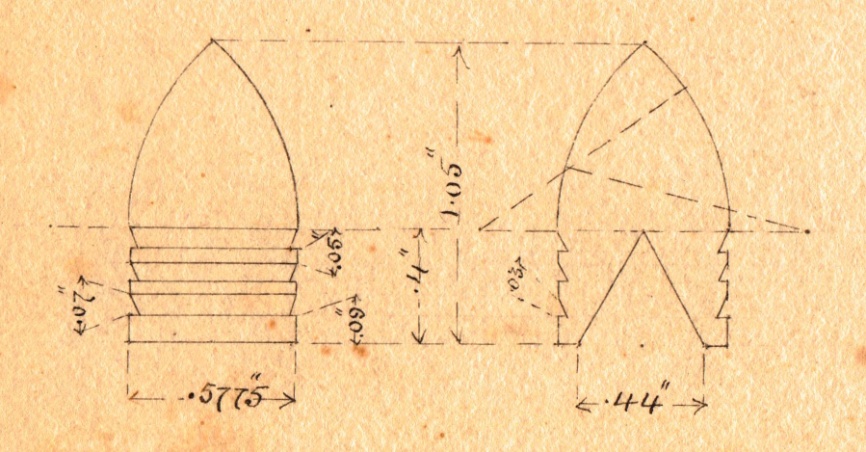

The U.S. Secretary of War at the time was Jefferson Davis (later to be the president of the Confederate States). He adopted the new bullet for the U.S. Army, in two sizes, a 0.69 caliber, and a 0.58 caliber (shown in the illustration on the previous page).

When the American Civil War broke out, both sides were still mostly using the old smoothbore muskets. As the war progressed, however, rifled muskets became much more common. The smoothbore weapons had an effective range of about 50 yards. The bullets could travel as far as 200 yards, but the accuracy was so poor that they were only effective at the shorter range. Rifles with the Miniè ball were effective at 300 yards, and the bullets flew as far as half a mile. The huge numbers of casualties in the Civil War can be traced to the more effective rifles, and the resistance of military leaders to adjust their tactics to the new realities.

Rifled cannon came into much more common use when breech loaded cannons were invented in the mid 1800’s.

Corned powder was not the last improvement made. In the 1800s, powder makers discovered that compressing the damp powder at high pressures (over 1,200 pounds per square inch) made it considerably denser. Denser explosives are more powerful, not only packing more power (and powder) into the same volume, but also getting the fuel and the oxidizer in even closer proximity. The dense hard cakes could no longer be forced through a sieve, but had to be broken first into pieces. The pieces were sieved, and any too large were broken further, while any too small were re-moistened and compressed into new cakes. The pieces were then tumbled with graphite in a drum. This gave them a polished coating of graphite, which both kept out moisture, and conducted electricity, making electric sparks less of a hazard.