A microtome is a simple device designed to make it easier to slice things into extremely thin slices for examining under the microscope.

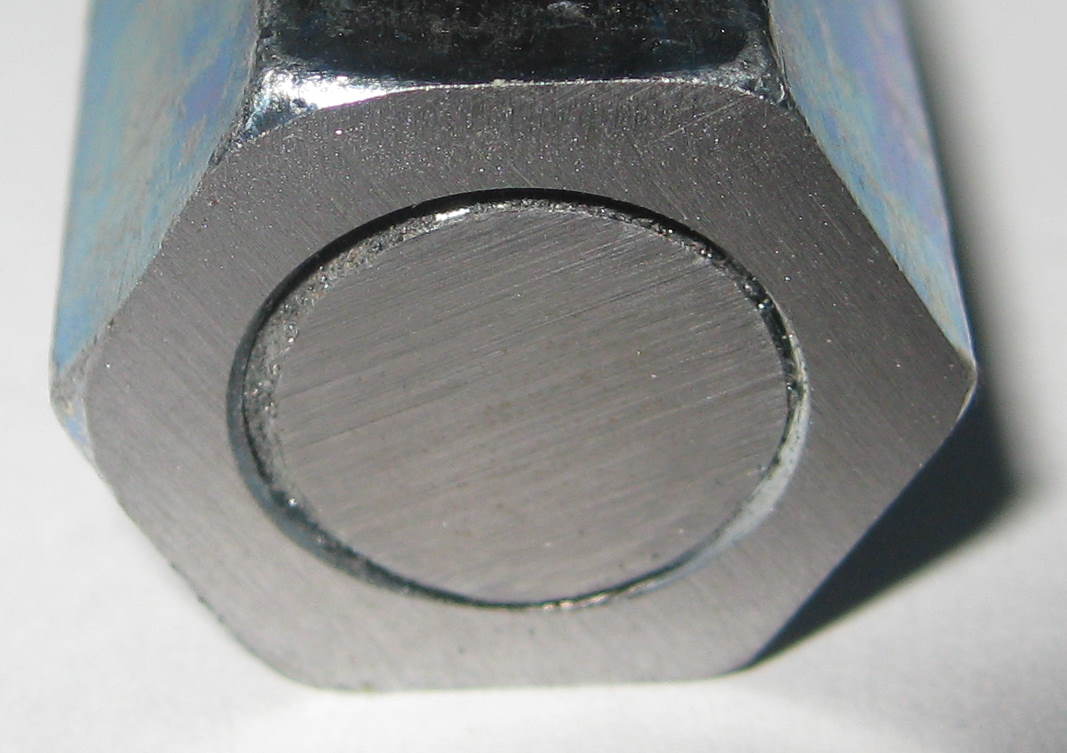

I made the microtome shown above from a long nut (called a union nut) and a carriage bolt. A hex bolt with a flat end would have been better, but the hardware store near me did not have any with threaded ends as long as the union nut. I wanted a long nut, but traditionally homemade microtomes are made with normal size nuts, and they work just fine.

I ground the end flat using sandpaper (power tools are nice for this, but it works fine if done by hand).

We want a flat face because we will be sliding a razor blade along the face of the microtome to slice off specimens.

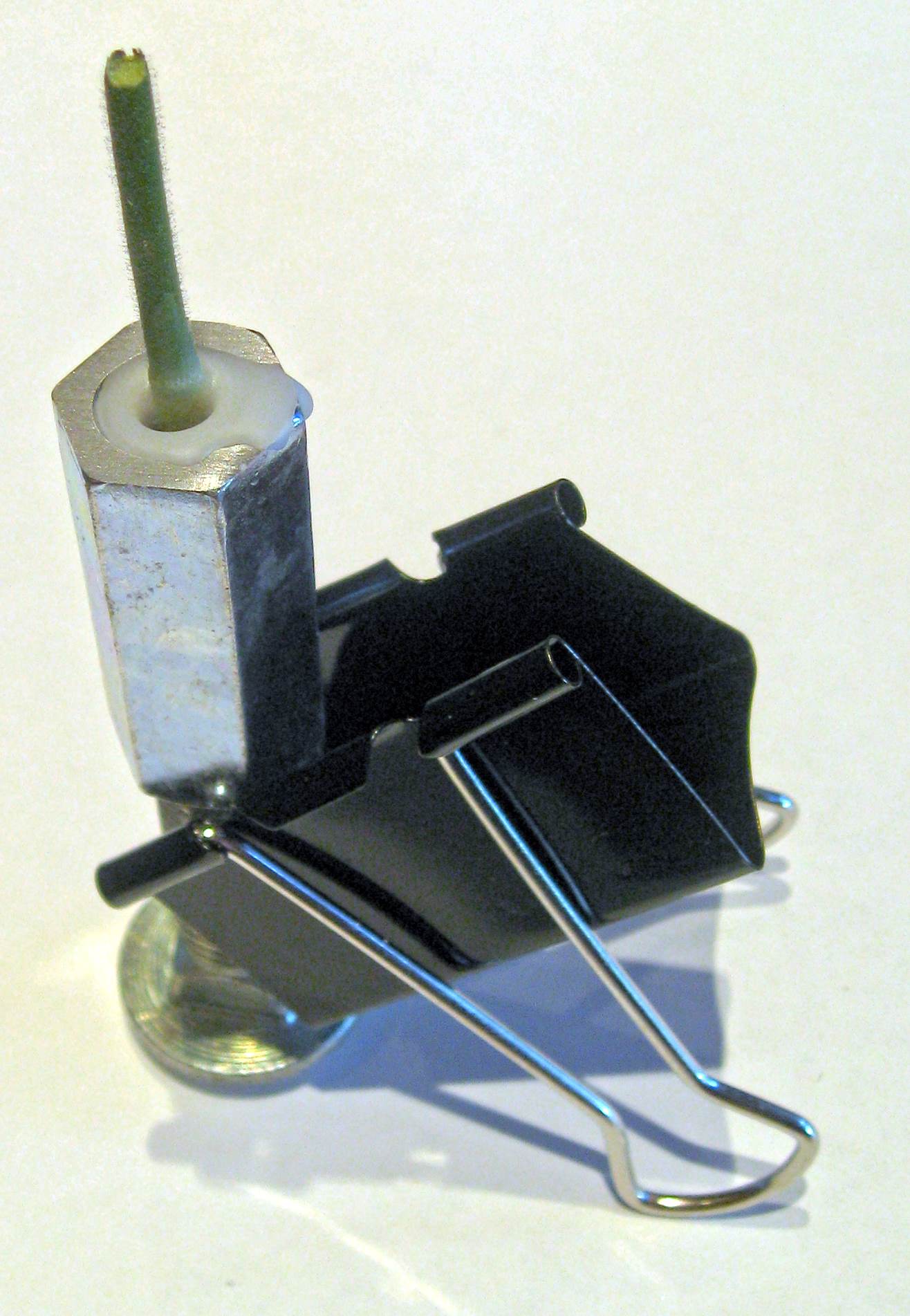

Because my microtome uses a carriage bolt with a domed end, it does not stand up by itself. So I use a binder clip to help it stand up straight, so we can place our specimen in it, and fill it up with paraffin wax. I think I'll grind the end flat later to make this more convenient.

Paraffin shrinks as it solidifies, and you can see that it has shrunk away from the specimen (a piece of geranium stem from the flower bed). This is normal. Once the paraffin has hardened, add some more to fill the gaps.

When the wax has hardened, we can use the microtome. With a smooth slicing motion, draw a single edge razor blade across and down over the face of the microtome, keeping pressure against the face, and keeping the very edge of the blade against the metal.

To make another slice, turn the bolt slightly to force the wax (with the specimen in it) out just a tiny bit. This will take some practice. At first it may be very hard to turn (especially if you went overboard like I did and used a long nut), so you may want to use wrenches to get it started.

My 5/8ths inch diameter bolt and nut use coarse threads, so there are 11 threads per inch. This means a full 360° turn will advance the wax by 1/11th of an inch, or 2.3 millimeters. One degree of turn will therefore advance the wax by 6.4 microns, and ten degrees will push it out 64 microns.

A bolt with fine threads would have 18 threads per inch, and 39 microns for a ten degree turn. An extra fine threaded bolt, with 24 threads per inch, would give 29 micron slices for each ten degree turn.

Extremely thin slices are difficult to make with a single edged razor blade, and commercial hand microtomes come with a straight razor and a micrometer screw, and range from $30 to $100. But with care and better knives, the homemade microtome can slice the same 10 micron slices that the commercial ones do.

There are also commercial electric microtomes for about $1,000 that are quite useful when sectioning lots of specimens daily. Some have blades made of glass, tungsten-carbide, or diamond.

To make a better knife, you can grind your own glass knife from a microscope slide using progressively finer grades of sandpaper, and finally honing it using scouring powder on a piece of plate glass. Another good knife can be made from the heavy blade of a carpenter's plane, again using scouring powder on glass as the final sharpening method. The stiffness of these two knives, and the fine sharpening, both help to get the thin sections we want.

Do not let the search for perfection interfere with using the simple single edged razor, however, as many good slides can be made using the slightly thicker sections it makes. You can also hone the razor on glass with scouring powder or jeweler's rouge to sharpen it. A piece of wood can also be used as a strop to straighten the thin edge before use.