- Science Toys

- Magnetism

- Electromagnetism

- Electrochemistry

- Radio

- Thermodynamics

- Aerodynamics

- Light and optics

- Simple laser communicator

- Make your own 3D pictures

- Making permanent rainbows.

- A solar powered marshmallow roaster

- Make a spectroscope from a CD.

- The impossible kaleidoscope

- Make a solar hotdog cooker

- Exploring invisible light

- A high resolution spectrograph.

- Time-lapse photography.

- High speed photography.

- Stacking photos for high depth of field.

- Biology

- Mathematics

- Computers and Electronics

Building simple heat engines.

Heat engines take many forms, from the internal combustion engine in the family car to the giant turbines that generate electricity for our homes. What they have in common is they steal some of the energy moving between something hot and something cold, and convert it into motion. When you heat a gas like air or steam, the molecules in the gas move around faster. The faster they move, the harder they hit anything that is in the way. If we put something in the way, such as a propellor or a pinwheel, we can make them spin (this is how turbine generators spin to create electricity). If we confine the gas in a container with a lid, we can pop the lid off (this is how the engine in a car works). If we let the fast moving molecules push on one side of a container, and escape through a small hole on the other side (so they are pushing on one side more than on the other) then we have a rocket or a jet, which moves in a direction away from the side with the hole. In this chapter we will make a working version of the first heat engine (a form of steam turbine), a gas turbine engine that runs from the small heat difference between your warm hand and the cooler air around it, and some tiny rockets that can be made in the kitchen in a couple minutes, and then shoot across a driveway.Hero's steam engine.

In the first century AD, the mathematician Hero of Alexandria described a device called the aeolipile, in which steam was conducted through pipes from a boiler to a sphere which had two jets from which the steam could escape. Hero's steam engine was probably a toy (if it was ever actually built) and not

put to any useful purpose. Continuing in that fine tradition, we will build

a version of his engine for the same purpose. Our version will be much

simpler to build, since we will need no steam-proof bearings for an axle.

We start with a tin can. The can will be both the boiler and the rotating

part with the jets. This simplification eliminates any need for steam to enter

the jet chamber through tight fitting bearings. We insert two thin brass tubes

into the can near the top, and opposite one another. We bend the tubes so they

are tangent to the can, and crimp them almost shut, so the steam pressure can

build up inside the can.

I have made several aeolipiles from various tin cans,

and some work better than others. Small cans like those tomato sauce comes in

work well, but they have no convenient screw tops through which to add water.

One must draw the water in through one tube by sucking on the other, which is

not a very dignified way to show off first century high technology. The best

can I have found to date is a small can used to hold 'Oatey Purple Primer', a

solvent for PVC plumbing pipe. This product is inexpensive, and easy to find

in most hardware stores. Pour out the contents into a jar and give it to

your favorite plumber, and wash out the can well.

The Oatey can has a wire soldered to the lid, and a ball of fibers at the other

end of the wire to act as a brush for applying the primer. Cut the wire off as

close to the lid as possible using diagonal wire cutters. Purists may unsolder

the wire, but this takes longer. Dispose of the wire, we won't be needing it.

Next we use a very small nail (actually I usually use an old jeweller's

screwdriver, but a small nail works fine) to punch two holes near the top of the

can (1/8th of an inch from the top, so we have a little wiggle room). The holes

must be directly across from one another, or the engine will wobble a lot (it will

wobble a lot anyway, so don't worry too much about precision). Two small

brass tubes, about one inch long and as thin as you can find now go into the

holes, one tube in each hole.

The brass tubing can be found in most hobby stores. It can be cut with the

diagonal cutters, but then one end must be filed down so it is wide open. The

other end can be opened by squeezing it with a pair of pliers, since we don't

want it open all the way. The tiny opening you get by squeezing makes a perfect

nozzle for the steam to escape.

The wide open end of the tube goes inside the can, and the nozzle end sticks out.

The tubes are pressed against the can so they are tangent to the can, rather than

sticking out straight.

Hero's steam engine was probably a toy (if it was ever actually built) and not

put to any useful purpose. Continuing in that fine tradition, we will build

a version of his engine for the same purpose. Our version will be much

simpler to build, since we will need no steam-proof bearings for an axle.

We start with a tin can. The can will be both the boiler and the rotating

part with the jets. This simplification eliminates any need for steam to enter

the jet chamber through tight fitting bearings. We insert two thin brass tubes

into the can near the top, and opposite one another. We bend the tubes so they

are tangent to the can, and crimp them almost shut, so the steam pressure can

build up inside the can.

I have made several aeolipiles from various tin cans,

and some work better than others. Small cans like those tomato sauce comes in

work well, but they have no convenient screw tops through which to add water.

One must draw the water in through one tube by sucking on the other, which is

not a very dignified way to show off first century high technology. The best

can I have found to date is a small can used to hold 'Oatey Purple Primer', a

solvent for PVC plumbing pipe. This product is inexpensive, and easy to find

in most hardware stores. Pour out the contents into a jar and give it to

your favorite plumber, and wash out the can well.

The Oatey can has a wire soldered to the lid, and a ball of fibers at the other

end of the wire to act as a brush for applying the primer. Cut the wire off as

close to the lid as possible using diagonal wire cutters. Purists may unsolder

the wire, but this takes longer. Dispose of the wire, we won't be needing it.

Next we use a very small nail (actually I usually use an old jeweller's

screwdriver, but a small nail works fine) to punch two holes near the top of the

can (1/8th of an inch from the top, so we have a little wiggle room). The holes

must be directly across from one another, or the engine will wobble a lot (it will

wobble a lot anyway, so don't worry too much about precision). Two small

brass tubes, about one inch long and as thin as you can find now go into the

holes, one tube in each hole.

The brass tubing can be found in most hobby stores. It can be cut with the

diagonal cutters, but then one end must be filed down so it is wide open. The

other end can be opened by squeezing it with a pair of pliers, since we don't

want it open all the way. The tiny opening you get by squeezing makes a perfect

nozzle for the steam to escape.

The wide open end of the tube goes inside the can, and the nozzle end sticks out.

The tubes are pressed against the can so they are tangent to the can, rather than

sticking out straight.

Now we solder the tubes to the can. Use a high wattage soldering gun or iron

(the Radio Shack 100 watt soldering gun works great), since the can will absorb

a lot of heat, and the little soldering pencils used for fine work in printed

circuit boards aren't good for the kind of plumbing we are doing. Always use

lead-free solder

on any toy or object that will be handled, especially by

children, who are more sensitive to lead poisoning.

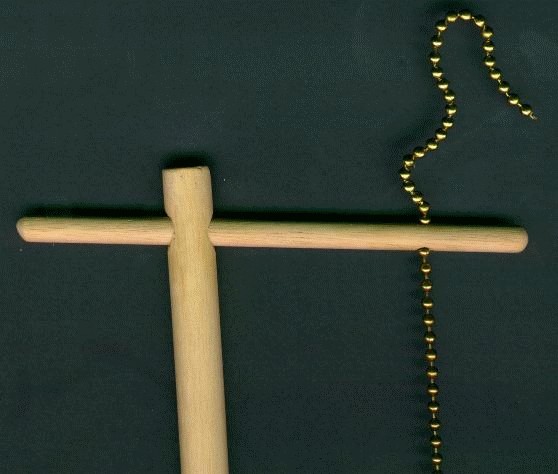

Now solder a length of

beaded brass chain

(the kind used as a pull chain to

turn lights on and off) to the top of the lid, in the center. This chain will

act as a support to hold up the engine, and as a bearing, to allow the engine

to spin. I have tried fishing swivels, and they work, but the chain has less

friction, and is cheaper (unless you have some fishing swivels lying around).

I usually solder the connector of the chain to the lid, since it is easier to

handle with a pair of long nosed pliers. But if you are making more than one

engine from one chain, you can simply solder one of the beads to the lid,

taking care that the hole in the bead where it connects to the rest of the chain

is straight up. The chain can be anything from 3 inches to a foot long,

depending on how far up you want to put the support (which we will describe

later).

Now we solder the tubes to the can. Use a high wattage soldering gun or iron

(the Radio Shack 100 watt soldering gun works great), since the can will absorb

a lot of heat, and the little soldering pencils used for fine work in printed

circuit boards aren't good for the kind of plumbing we are doing. Always use

lead-free solder

on any toy or object that will be handled, especially by

children, who are more sensitive to lead poisoning.

Now solder a length of

beaded brass chain

(the kind used as a pull chain to

turn lights on and off) to the top of the lid, in the center. This chain will

act as a support to hold up the engine, and as a bearing, to allow the engine

to spin. I have tried fishing swivels, and they work, but the chain has less

friction, and is cheaper (unless you have some fishing swivels lying around).

I usually solder the connector of the chain to the lid, since it is easier to

handle with a pair of long nosed pliers. But if you are making more than one

engine from one chain, you can simply solder one of the beads to the lid,

taking care that the hole in the bead where it connects to the rest of the chain

is straight up. The chain can be anything from 3 inches to a foot long,

depending on how far up you want to put the support (which we will describe

later).

Next take the lid of the can and use it to trace a circle around some rubber

sheet, either a piece of an old inner tube, or a bit from a tire patch kit.

Cut out the circle and push it into the lid of the can as a seal (called a

gasket) to keep the steam from coming out where it shouldn't.

The support is made of three pieces of wood. One piece is the base, which can

be any flat piece of wood such as a 2x4. I found some nice pieces in a hobby

store that had been shaped for plaques that work nicely. The base should be

large enough that the engine does not topple over as it wobbles around. A

minimum is probably 3 by 5 inches.

Two wooden dowels form the rest of the support. One dowel is a half inch or more

in diameter and about 15 inches long, and forms the mast.

Drill a hole in the base that fits the mast

snuggly. If the fit is not tight, you can use glue to hold the pieces together.

The last piece is a small dowel about 5 inches long and a quarter of an inch

in diamter. Drill a quarter inch diameter hole in the mast about an inch from

the top, and force the small dowel into it. The fit does not have to be snug,

but a snug fit will keep the pieces together when the engine is transported.

Do not glue this part, since it will be adjusted later.

The small dowel must also have a hole drilled through it about an inch from the

end. This hole should be just a little larger than the beaded chain, since the

chain will be threaded through this hole. If the fit is a little snug, you will

not need anything more to hold the chain in place. If it is loose, then a little

bit of wire can be wrapped around the chain above the hole to keep the chain from

falling through when the can is full of water.

Next take the lid of the can and use it to trace a circle around some rubber

sheet, either a piece of an old inner tube, or a bit from a tire patch kit.

Cut out the circle and push it into the lid of the can as a seal (called a

gasket) to keep the steam from coming out where it shouldn't.

The support is made of three pieces of wood. One piece is the base, which can

be any flat piece of wood such as a 2x4. I found some nice pieces in a hobby

store that had been shaped for plaques that work nicely. The base should be

large enough that the engine does not topple over as it wobbles around. A

minimum is probably 3 by 5 inches.

Two wooden dowels form the rest of the support. One dowel is a half inch or more

in diameter and about 15 inches long, and forms the mast.

Drill a hole in the base that fits the mast

snuggly. If the fit is not tight, you can use glue to hold the pieces together.

The last piece is a small dowel about 5 inches long and a quarter of an inch

in diamter. Drill a quarter inch diameter hole in the mast about an inch from

the top, and force the small dowel into it. The fit does not have to be snug,

but a snug fit will keep the pieces together when the engine is transported.

Do not glue this part, since it will be adjusted later.

The small dowel must also have a hole drilled through it about an inch from the

end. This hole should be just a little larger than the beaded chain, since the

chain will be threaded through this hole. If the fit is a little snug, you will

not need anything more to hold the chain in place. If it is loose, then a little

bit of wire can be wrapped around the chain above the hole to keep the chain from

falling through when the can is full of water.

With the large dowel snug in the hole in the base, and the smaller dowel fitting

in the hole near the top of the larger dowel, the chain now suspends the can

a little above the base. Raise the chain enough to fit a small can of Sterno

(jellied alcohol, used to keep food warm at buffets) under the Oatey can. Leave

about a half of an inch between the two cans so air can get to the alcohol.

With the large dowel snug in the hole in the base, and the smaller dowel fitting

in the hole near the top of the larger dowel, the chain now suspends the can

a little above the base. Raise the chain enough to fit a small can of Sterno

(jellied alcohol, used to keep food warm at buffets) under the Oatey can. Leave

about a half of an inch between the two cans so air can get to the alcohol.

Now fill the can with water, tighten the lid firmly, and light the Sterno to

boil the water in the steam engine. If the can is full of water it will take

a few minutes to boil. If the can has only a half inch or so of water, it will

boil much sooner. Be careful not to let the can run dry, or the can will become

an ugly color, the solder will melt, and the rubber gasket will smoke and stink.

As the water boils, the can will start to spin. The steam coming out the brass

tubes should be cool enough to touch (I'll explain

why

later). If the steam does not exit with enough force to spin the can, there

may be too much friction on the chain (too short a chain, not a brass chain,

too heavy a can) but more likely the problem is with the nozzles. The nozzles

must have very small openings, so the steam pressure can build up in the can,

making the steam exit the nozzles at high speed. Try pinching the nozzles shut

a little more using a pair of pliers. Make sure there is some small hole

in each, or the can will rupture from the pressure. I have built several of

these, and all of them worked the first time, although the ones with the smallest

holes spin fastest.

As the can spins faster and faster, it will start to wobble. Even if you have

built everything with the utmost precision, the water in the can is boiling, and

there will be bubbles that make one side lighter than the other. You can ease

the wobble quite a bit by holding the chain near the can, so the effective length

of the chain is shorter. Be careful not to touch anything hot.

Now fill the can with water, tighten the lid firmly, and light the Sterno to

boil the water in the steam engine. If the can is full of water it will take

a few minutes to boil. If the can has only a half inch or so of water, it will

boil much sooner. Be careful not to let the can run dry, or the can will become

an ugly color, the solder will melt, and the rubber gasket will smoke and stink.

As the water boils, the can will start to spin. The steam coming out the brass

tubes should be cool enough to touch (I'll explain

why

later). If the steam does not exit with enough force to spin the can, there

may be too much friction on the chain (too short a chain, not a brass chain,

too heavy a can) but more likely the problem is with the nozzles. The nozzles

must have very small openings, so the steam pressure can build up in the can,

making the steam exit the nozzles at high speed. Try pinching the nozzles shut

a little more using a pair of pliers. Make sure there is some small hole

in each, or the can will rupture from the pressure. I have built several of

these, and all of them worked the first time, although the ones with the smallest

holes spin fastest.

As the can spins faster and faster, it will start to wobble. Even if you have

built everything with the utmost precision, the water in the can is boiling, and

there will be bubbles that make one side lighter than the other. You can ease

the wobble quite a bit by holding the chain near the can, so the effective length

of the chain is shorter. Be careful not to touch anything hot.

Why does it do that?

As the water heats up, the molecules of water move faster. When the water boils, the molecules are moving too fast to stay stuck together as a liquid, and they move about freely as steam. The fast moving water molecules are bouncing around in the can, hitting the walls of the can from all directions. Because they hit the top as often as they hit the bottom, the can neither moves up nor down. But there is one direction in which the molecules don't hit anything. This is the direction where the holes in the tubes are. Instead of hitting a wall of the can, the molecules hit nothing, and exit out into the air. The molecules in the can are pushing on all the walls the same amount, except where the holes are. Because nothing is pushing in that direction, there is nothing to hold the can back, and it moves away from the holes in the tubes. Imagine a big box on the floor, with no top, no bottom, and one wall missing. Imagine inside the box are ten little kids, all running in different directions. When a kid runs into the wall of the box, the box moves a little bit, and the kid bounces off the wall and runs in another direction. Let's call the walls the left wall, the right wall, and the front wall. The back wall is the one that is missing. Some kids will hit the left wall, and the box will move to the left. Some kids will hit the right wall, and the box will move to the right. These movements will cancel each other out, and the box will stay in the center of the room. Each time a kid hits the front wall, the box will move towards the front. But since there is no back wall, no kids will ever move the box back. The result is a box that is moving across the room. Rockets and jets move the same way the box moves. A rocket can work in outer space because it does not need to push against air or the ground. It works because the molecules inside the rocket are pushing in every direction except out the back. Our steam engine works because it has two rockets (the brass tubes) pushing the sides of the can in opposite directions, causing it to spin.Why is the steam cool when it comes out?

The steam is hot inside the can because of two things: the speed of the molecules, and the number of molecules crammed into that little space. The speed of the molecules is what creates the temperature. But temperature alone is not what burns your fingers. You need a lot of fast moving molecules hitting your fingers before you can feel it as heat. When the fast moving molecules of steam leave the nozzles, they spread out in all directions as they run into the slow moving air molecules outside the can. What you feel with your hand is the steam molecules that have slowed down in the air, and the air molecules they bumped into and caused to move. Not only have they slowed down by the time they hit your hand, but they have spread out so they don't all hit the same place. The combination of moving slowly and spreading out makes them feel cool on your hand.The worlds simplest steam powered boat

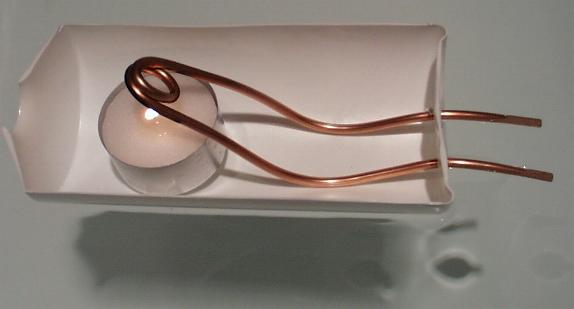

This next toy is an example of the simplest steam engine you will ever see. It has no valves, no moving parts (in the traditional sense of the phrase), and yet it can propel it's little boat easily across the largest swimming pool or quiet duck pond. The photograph above tells nearly all the construction details.

The boat is a plastic bottle, cut in half lengthwise. I used a soft plastic

bottle that contact lens saline solution comes in. It is made of white High

Density Polyethylene (HDPE), and is very easy to cut using an Xacto knife or

other sharp utility knife.

Near the bow of the boat is a small candle, such as those used to keep food

warm on the table. I chose a candle that comes with a small aluminum can,

and is less than an inch high, so it would sit low in the boat and not drip

wax all over. The aluminum cup keeps the melted wax in place, so the boat

can go for hours. I used a small amount of sticky tape to keep it in place.

The engine is made of 1/8 inch soft copper tubing. This can be found at the

better hardware stores, and is normally used in refrigerators. You can use

the easier to find 1/4 inch soft copper tubing, but the 1/8 works best with

the candle's small heat source, and weighs less, so it is less likely to tip

the boat.

The best way to cut the tubing is with a tubing cutter (get it at the hardware

store when you get the tubing). You can use a hacksaw, but you will have to

clean the debris out of the cut with a knife or sandpaper.

Gently bend the tubing around a large pen or pencil (I used the handle of a

wooden spoon) to form the coil in the center. Poke two holes in the back of

the boat with a nail, and force the copper tubes through the holes. The holes

in the soft plastic will close around the tubing, forming a water-tight fit.

It is also possible to simply lay the tubing on the top of the back part of

the boat, and then bend it down so the ends are under water, and pointing to

the rear.

Gently bend the tubing so the coil is just above the top of where the

candle flame will be. The boat is now finished, and ready to launch.

The copper tubes must be full of water, and both open ends must be under

water. The easy way to fill the tubes is to hold one end under water,

and suck on the other end.

When the tubes are full of water, and the boat is resting in the water with

both ends of the tubing under the water, light the candle.

When the coil of copper tubing is hot enough to boil the water inside, the

boat will jerk ahead suddenly, then start moving evenly forward. If you

put your fingers in the water just behind the tubes, you can feel little

pulses of water, about 5 or 10 pulses per second. These pulses are pushing

the boat along.

The photograph above tells nearly all the construction details.

The boat is a plastic bottle, cut in half lengthwise. I used a soft plastic

bottle that contact lens saline solution comes in. It is made of white High

Density Polyethylene (HDPE), and is very easy to cut using an Xacto knife or

other sharp utility knife.

Near the bow of the boat is a small candle, such as those used to keep food

warm on the table. I chose a candle that comes with a small aluminum can,

and is less than an inch high, so it would sit low in the boat and not drip

wax all over. The aluminum cup keeps the melted wax in place, so the boat

can go for hours. I used a small amount of sticky tape to keep it in place.

The engine is made of 1/8 inch soft copper tubing. This can be found at the

better hardware stores, and is normally used in refrigerators. You can use

the easier to find 1/4 inch soft copper tubing, but the 1/8 works best with

the candle's small heat source, and weighs less, so it is less likely to tip

the boat.

The best way to cut the tubing is with a tubing cutter (get it at the hardware

store when you get the tubing). You can use a hacksaw, but you will have to

clean the debris out of the cut with a knife or sandpaper.

Gently bend the tubing around a large pen or pencil (I used the handle of a

wooden spoon) to form the coil in the center. Poke two holes in the back of

the boat with a nail, and force the copper tubes through the holes. The holes

in the soft plastic will close around the tubing, forming a water-tight fit.

It is also possible to simply lay the tubing on the top of the back part of

the boat, and then bend it down so the ends are under water, and pointing to

the rear.

Gently bend the tubing so the coil is just above the top of where the

candle flame will be. The boat is now finished, and ready to launch.

The copper tubes must be full of water, and both open ends must be under

water. The easy way to fill the tubes is to hold one end under water,

and suck on the other end.

When the tubes are full of water, and the boat is resting in the water with

both ends of the tubing under the water, light the candle.

When the coil of copper tubing is hot enough to boil the water inside, the

boat will jerk ahead suddenly, then start moving evenly forward. If you

put your fingers in the water just behind the tubes, you can feel little

pulses of water, about 5 or 10 pulses per second. These pulses are pushing

the boat along.

In the photograph above, the candle has been replaced with a lump of

charcoal starter cake. This makes a bigger flame, and makes the boat

move even faster. The candle is safer, however.

In the photograph you may be able to just barely see the ripples in

the water behind the boat. These ripples are caused by the 5 to 10

pulses per second that the engine makes as it operates. The easiest

way to view this is to watch the reflection of a bright light on the

surface of the water.

In the photograph above, the candle has been replaced with a lump of

charcoal starter cake. This makes a bigger flame, and makes the boat

move even faster. The candle is safer, however.

In the photograph you may be able to just barely see the ripples in

the water behind the boat. These ripples are caused by the 5 to 10

pulses per second that the engine makes as it operates. The easiest

way to view this is to watch the reflection of a bright light on the

surface of the water.

How does it do that?

When the water in the coil boils, the steam expands. This pushes the water out of the tubes. The reaction pushes the boat forward, as we explained above (and will explain in a different way when we look at rockets in a little bit). As the steam continues to expand, it encounters the section of tubing that used to be full of water. This tubing is cold, and the steam condenses back into water. This causes a vacuum to form, which pulls more water back into the tubes. You would expect that the water moving back into the tubing would cause the boat to go backwards. However, the water doesn't get very far before it hits the end of the tube (the two streams of water in the two tubes meet each other in the coil). Any motion caused by the water being sucked into the tubes is reversed by the water hitting the front of the tube (the coil) and pushing the boat forward again. As you saw when you put your finger near the tubes, this back and forth water motion is fairly rapid, and the comparatively heavy boat never actually moves backwards at all. You can see a really nice little hand-made steamboat in our catalog, and shown below:

Click on photo for a larger picture These are made in India on hand-operated presses, from tin plated steel. They are then hand-painted. They make a wonderfully loud "putt-putt-putt" sound as the steam around a bathtub, swimming pool, or pond. They come with a tiny candle, and also a little wick so you can use olive oil as a fuel, which will run the engine for hours. You can click here to see a video (with sound) of the little boat speeding around a bathtub. The video is 1,348,276 bytes long, and will take a little while to download, so be patient.

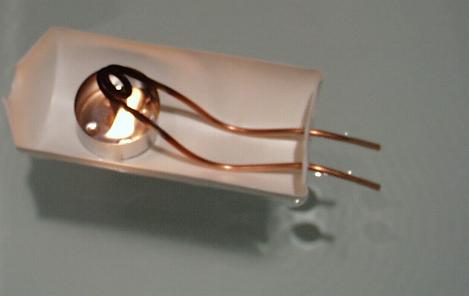

A rotary steam engine

We can use the same steam engine that pushes the boat in a different way. We can arrange that the engine causes something to turn. We start with an aluminum soft drink can, which we cut about a third of the way up from the bottom to form a small cup. We then carefully (so as not to cut our fingers) bend over the sharp

edge, and crimp it with a pair of pliers to form a neat edge. Don't

worry too much about neatness, since it will not affect the operation

of the engine, only the looks.

We also put a large dent in the bottom of the can, which is normally

bowed up in a dome, which is inconvenient, since we want to put a candle

there later. We punch two neat holes in the side of the can, opposite

one another, with a paper punch. These holes will hold our copper tubing.

We then carefully (so as not to cut our fingers) bend over the sharp

edge, and crimp it with a pair of pliers to form a neat edge. Don't

worry too much about neatness, since it will not affect the operation

of the engine, only the looks.

We also put a large dent in the bottom of the can, which is normally

bowed up in a dome, which is inconvenient, since we want to put a candle

there later. We punch two neat holes in the side of the can, opposite

one another, with a paper punch. These holes will hold our copper tubing.

Next we put in the candle, using the same kind of candle

(with its convenient little cup to hold the melted wax)

as we used for the boat. Around the candle, we put a rope

of crumpled aluminum foil, to keep the candle centered in the can.

Next we put in the candle, using the same kind of candle

(with its convenient little cup to hold the melted wax)

as we used for the boat. Around the candle, we put a rope

of crumpled aluminum foil, to keep the candle centered in the can.

Now we make the tubing coil in the same way as we did for the boat.

This time, however, we bend the ends out to fit through the punched

holes. This is a little tricky to do at first, but you soon get

good at it. In the version shown, I have added an extra coil to the

engine, but this is not necessary, and does not improve the engine.

Now we make the tubing coil in the same way as we did for the boat.

This time, however, we bend the ends out to fit through the punched

holes. This is a little tricky to do at first, but you soon get

good at it. In the version shown, I have added an extra coil to the

engine, but this is not necessary, and does not improve the engine.

Next we bend the ends of the tubing gently so they curve into a right

angle. Each end is bent opposite the other, so the can will spin when

it is placed in the water and the engine started.

Next we bend the ends of the tubing gently so they curve into a right

angle. Each end is bent opposite the other, so the can will spin when

it is placed in the water and the engine started.

The final photograph shows the engine in operation. With a candle, it

spins at about one rotation per second.

The final photograph shows the engine in operation. With a candle, it

spins at about one rotation per second.

A simple rocket engine you can build in your kitchen

There is a fascination about rockets that delights children and adults alike. The arc of smoke, the idea of flight, and the fun of action at a distance combine to make rockets a wonderful toy. To these pleasures we will add the forbidden glee of playing with matches, and the satisfaction of learning how something magical actually works. Unlike most of the rest of this book, this really is rocket science. The rockets we are about to build are perhaps the smallest toys in this book. They travel about ten feet, which is nonetheless 150 times their length. They are hot to the touch, and can blister a hand that catches them, so care must be used to fire them only outdoors, on a fireproof surface such as a driveway. Since they are notoriously inaccurate, the center of the driveway is suggested, so they don't land in dry grass somewhere. As always when playing with things that burn, a source of water such as a bucket or garden hose should be nearby in case of accidents. These rockets are made out of aluminum foil and match heads, and take less than a minute each to manufacture. You will need a book of paper matches (or a box of wooden matches), a sheet of aluminum foil, a pair of scissors, a paper clip, and a straight pin. Start by cutting a narrow strip of aluminum foil, about 1 inch wide and three inches long. Tear the head off of a paper match (or cut it off with the scissors), leaving as little of the paper as possible attached to the matchhead. Set the matchhead on the foil near one end, with the top of the head facing down towards you. Roll the edge of the foil over the matchhead, forming a tube with the matchhead

firmly in the center. Unfold the paper clip and insert one end of the wire

into the tube so it touches the top of the matchhead (not the paper). Now press

the foil tube flat to hold everything in place.

Roll the edge of the foil over the matchhead, forming a tube with the matchhead

firmly in the center. Unfold the paper clip and insert one end of the wire

into the tube so it touches the top of the matchhead (not the paper). Now press

the foil tube flat to hold everything in place.

Fold the foil over one more time (or twice if you like), and tear off the excess

foil.

Now twist the foil at

the free end tightly (without tearing it). Twist the end with the paper clip

tightly around the paper clip, keeping the wire touching the matchhead at all

times.

Fold the foil over one more time (or twice if you like), and tear off the excess

foil.

Now twist the foil at

the free end tightly (without tearing it). Twist the end with the paper clip

tightly around the paper clip, keeping the wire touching the matchhead at all

times.

Lastly, cut off the excess foil from the top of the rocket (the end away from

the paper clip). We are now finished with the rocket, and we are ready to build

the launcher.

The rocket launcher is a straight pin stuck through a piece of cardboard (such as

an empty matchbook) or a wad of aluminum foil. The pin should point upwards at

a 45 degree angle. The rocket is removed from the paper clip, and slipped over

the pin, so the pin is now where the paper clip used to be.

Lastly, cut off the excess foil from the top of the rocket (the end away from

the paper clip). We are now finished with the rocket, and we are ready to build

the launcher.

The rocket launcher is a straight pin stuck through a piece of cardboard (such as

an empty matchbook) or a wad of aluminum foil. The pin should point upwards at

a 45 degree angle. The rocket is removed from the paper clip, and slipped over

the pin, so the pin is now where the paper clip used to be.

To launch the rocket, first aim it in a safe direction,

where it won't start a

fire or melt anything it hits. Then light a match,

and hold it under the rocket.

To launch the rocket, first aim it in a safe direction,

where it won't start a

fire or melt anything it hits. Then light a match,

and hold it under the rocket.

The heat of the flame will cause the matchhead to catch

fire inside the foil.

The hot gases from the matchhead will have only one

way to escape -- through the

hole where the pin is. As the gases go one way,

the rocket goes the other, with

a sharp hiss, and a trail of smoke.

The heat of the flame will cause the matchhead to catch

fire inside the foil.

The hot gases from the matchhead will have only one

way to escape -- through the

hole where the pin is. As the gases go one way,

the rocket goes the other, with

a sharp hiss, and a trail of smoke.

Depending on how big the matchhead was, and

how much foil was used,

the rocket will travel anywhere from a few inches to 20

feet.

Depending on how big the matchhead was, and

how much foil was used,

the rocket will travel anywhere from a few inches to 20

feet.

If your rocket does not fly, but instead bursts through the side of the foil, you

need to build one with more foil (by rolling it one more time before tearing off

the excess foil). If it hisses but doesn't leave the pin, check to make sure

that the rocket slides easily up and down the pin. The pin should not block the

tube completely, but should leave some space between it and the foil. In other

words, the pin should be skinnier than the paper clip. Be careful not to squash

the tube flat while handling the rocket.

If your rocket does not fly, but instead bursts through the side of the foil, you

need to build one with more foil (by rolling it one more time before tearing off

the excess foil). If it hisses but doesn't leave the pin, check to make sure

that the rocket slides easily up and down the pin. The pin should not block the

tube completely, but should leave some space between it and the foil. In other

words, the pin should be skinnier than the paper clip. Be careful not to squash

the tube flat while handling the rocket.

How does it do that?

A matchhead makes a good rocket fuel because it carries both the burnable material and the oxygen needed to burn it. The burnable material in this case is the sulfur in the matchhead. The oxygen comes from compounds like potassium chlorate and potassium nitrate that are mixed with the sulfur. When the matchhead is heated, the sulfur and the potassium chlorate combine to make sulfur dioxide gas, and potassium chloride. This generates a lot of heat, which heats up the gases. The hot gases are under a lot of pressure, and their molecules hit the walls of the rocket at great speed. Where the nozzle of the rocket lets the gases out, there is no wall to hit, so there are no molecules pushing in that direction. The difference in pressure between the nozzle end (no pressure) and the opposite end (high pressure) is what pushes the rocket forwards. Next: More thermodynamic toys... For more information on thermodynamics, see the Recommended Reading section. Order steamboat toys here. Del.icio.us- Science Toys

- Magnetism

- Electromagnetism

- Electrochemistry

- Radio

- Thermodynamics

- Aerodynamics

- Light and optics

- Simple laser communicator

- Make your own 3D pictures

- Making permanent rainbows.

- A solar powered marshmallow roaster

- Make a spectroscope from a CD.

- The impossible kaleidoscope

- Make a solar hotdog cooker

- Exploring invisible light

- A high resolution spectrograph.

- Time-lapse photography.

- High speed photography.

- Stacking photos for high depth of field.

- Biology

- Mathematics

- Computers and Electronics

Some of my other web sites:

Send mail to Simon Quellen Field via [email protected]